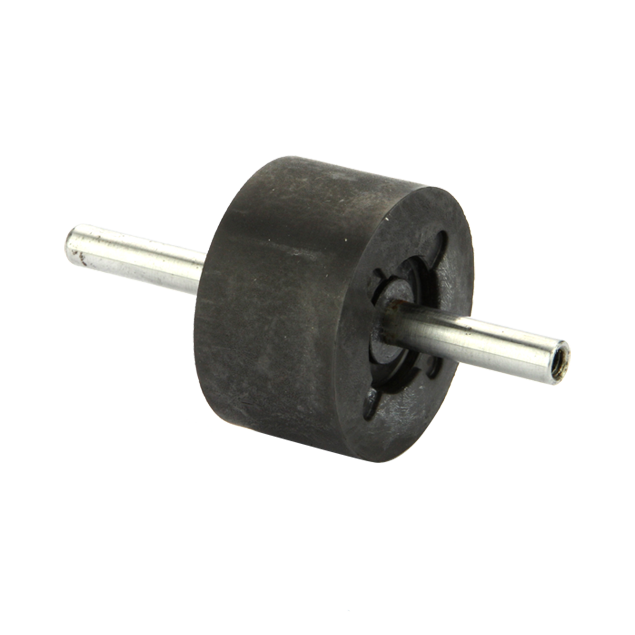

Ferrite Injection

Trade Terms :

EXW, FOB Ningbo, Door to door

Place of Origin :

Ningbo City, Zhejiang Province, China

Certificate :

IATF16949, ISO9001:2015

Payment Terms :

T/T

Delivery Time:

7-20 working days for making sample, 20 to 50 working days for production it depends on the mass quantities